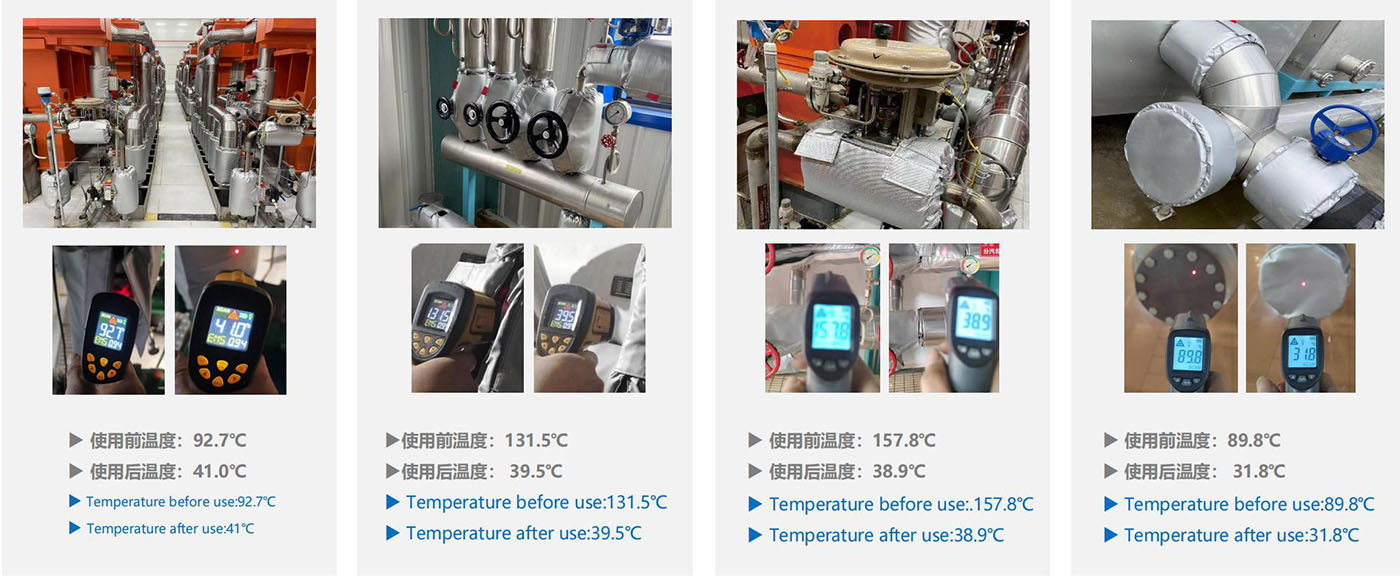

The effects after the installation of industrial insulation jackets

After the installation of our Industrial Insulation jacket is completed, its effectiveness gradually becomes apparent. The insulation jacket fits tightly to the surface of the equipment, like putting a "thermal coat" on the equipment, which effectively reduces heat loss, lowers energy consumption, and saves operational costs for the enterprise. At the same time, the installed insulation jacket can also protect the equipment, reducing the damage caused by thermal expansion and contraction due to temperature changes and extending the service life of the equipment. In addition, it improves the working environment, avoids the risk of scalding caused by operators contacting high-temperature equipment, and greatly enhances operational safety.

These achievements are attributed to precise measurement in the early stage, selection of high-quality materials, and professional installation techniques. If you are interested in the maintenance of industrial insulation jackets or more application scenarios, feel free to let me know.

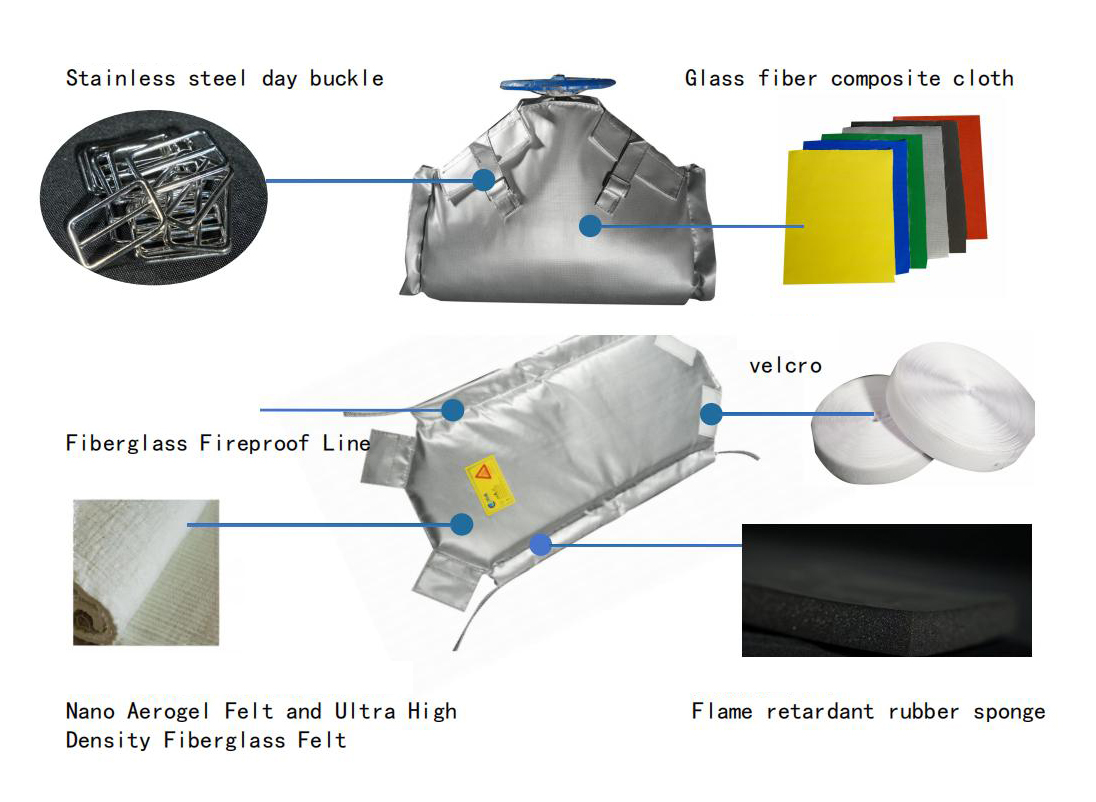

Advantages of Industrial Insulation Jacket Materials

Industrial insulation jackets leverage specialized materials to address diverse operational challenges, offering key advantages in thermal performance, durability, and safety. Below are the core benefits of common Insulation Materials:

1. High-Temperature Resistance Materials

Extreme Heat Protection: Withstands temperatures up to 1,400°C (2,552°F), making it ideal for furnaces, boilers, and exhaust systems in steel, glass, and power industries.

Lightweight Design: Up to 70% lighter than traditional refractories, reducing equipment load while maintaining thermal stability.

Low Thermal Conductivity: As low as 0.03 W/m·K, minimizing heat loss and cutting energy costs by 15–30%.

Here are the on-site temperature comparison charts and post-installation effect diagrams of our company's installation.